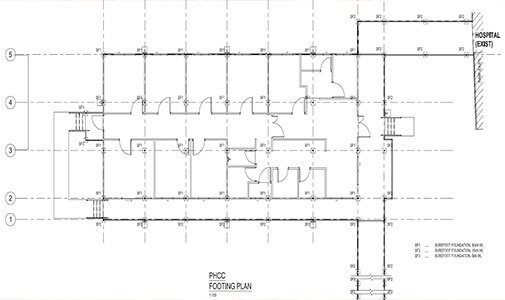

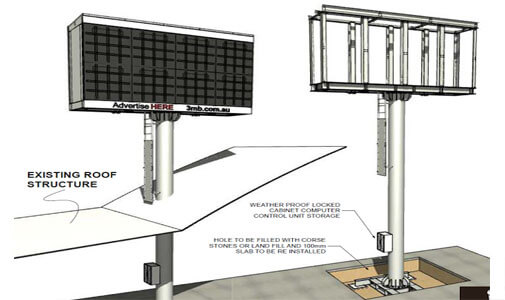

Located in the north of Western Australia, Karratha has the highest rating in cyclone classification in Australia. That aspect made Surefoot a viable candidate as the footing option for the project of a cantilevered Roof structure in three local Skate Parks because of the high capcity for uplift loads that Surefoot offers. The option of using concrete was prohibitive due to the fact that there was an existing structure close to the proposed roof and there was no access to excavation.

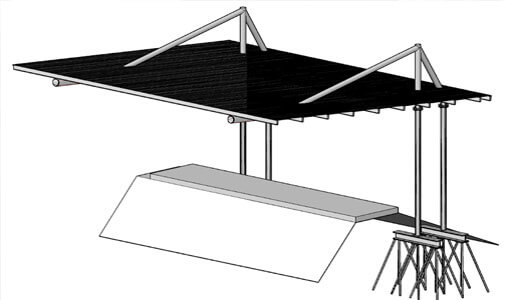

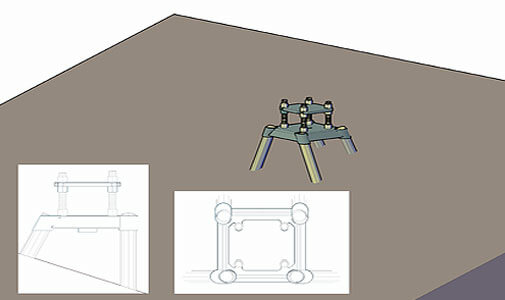

The design consisted on a roof supported by two sets of columns in the back end of the structure. The engineering team received the structural design and the soil tests for the locations of the structures. The maximum uplift force for the supports was 470kN. That force prompted the design of a combination frame using multiple Surefoot caps to resist such force.